You can do it

Measure your company’s carbon footprint

and change the tide!

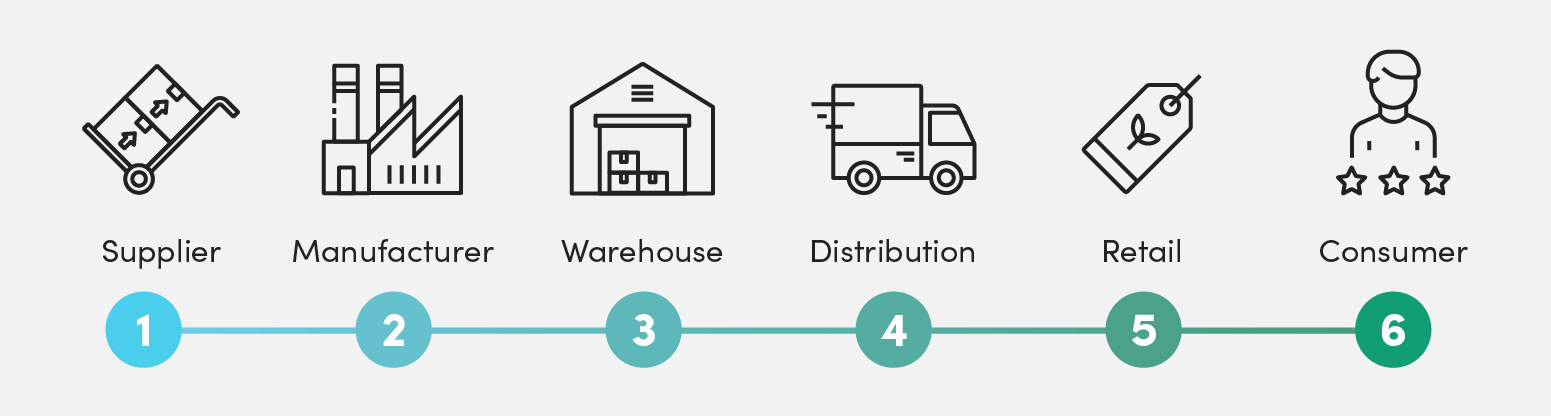

The carbon footprint is a single index indicator for our participation in climate change, which measures the entire amount of CO2 emitted throughout a production chain.

Any crystal specimen, polished crystal product, and jewelry piece that reaches the final consumer has gone through a whole chain of production, more or less long, from the extraction of raw materials (minerals in our case) to the finished product, passing through the design, the processing, promotion, distribution, and transportation.

In each of these steps or links in the chain, a bit of additional carbon footprint is added until reaching that final consumer.

The receiver of all that footprint that has been accumulating along the production chain is the final consumer, the customer who is sitting at his living room table enjoying his crystal.

However, all the links in the chain have been intermediate consumers (as temporary holders) of the product that has been passing through all of them. Also, each link of the chain is at the same time a final consumer of many other products (from a pen to a grinding wheel) that no longer pass to the next link.

Each one of the production steps acquires the footprint from the previous step and generates a new additional footprint through their own processes.

To make it clear in a real-world example:

If you buy a crystal from Gemrock you are now owning the footprint we generated because this product was made for you. So of course it is a benefit for you if we are active to reduce our footprint because the negative footprint you acquire when buying our product is smaller.

Once you have the crystal (and its footprint) in your possession, you add your own footprint = the sum of all emissions generated by:

-

- your infrastructure use,

- the services you hire (accounting, internet, etc.),

- the water and electricity you consume,

- the office materials you use,

- the marketing costs,

- the packaging costs,

- the cost of treating the waste generated by your company, and

- the shipping cost to you your client.

Once your client has received the crystal he not only owns this product but the entire footprint generated along the chain.

From January 2025 on we will include the cost of neutralizing our carbon footprint into our price.

To give you an example: We could calculate that every dollar spent by a wholesale client of ours corresponds to a carbon footprint of 439 gr CO2. Meaning, that if you buy from us a crystal for a price of 100 USD (including shipping) then the carbon footprint of this crystal when it arrives at your shop is 43.94 kilos CO2 and the additional cost to eliminate this carbon footprint is 1.- USD. Your new price will be 101 USD to receive a carbon-neutral crystal that has cero climate change impact.

However, your company’s activities will cause a new carbon footprint. To know how much carbon footprint your operation adds to the product you must calculate your companies´ carbon footprint. We can help you doing this.

How to calculate a carbon footprint:

The method we used to calculate our company’s carbon footprint is based on the methodology developed by Rees and Wackernagel in 1996, which measures all the impacts produced by a population, expressed in hectares of ecosystems or “nature” being used. This method can be applied on all scales from countries to cities, to companies, or to individuals.

It is a method to calculate the so-called “ecological footprint”. The ecological footprint is even more complete than a carbon footprint because it measures more things. However, the problem is that the ecological footprint cannot really be quantified in economic terms. It is more of a comparative tool.

The carbon footprint on the contrary can be monetized: the monetary cost is the cost of planting and maintaining trees to eliminate the CO2 emissions.

The good thing about the method developed by the two scientists is that the ecological footprint includes the calculation of the carbon footprint as part of the equation. The method therefore is perfectly applicable for calculating the carbon footprint. It was used in 2007 by Juan Luis Domenech Quesada to calculate the ecological footprint and the carbon footprint of the port of Gijon in Argentina. Therefore, the tables we are using have been tested in real life.

Stefan Austermühle, General Manager of Gemrock Peru, has used this method as an environmental consultant from 2010 to 2013 to measure the carbon footprint of 14 Peruvian companies, from travel agencies to hotels, rainforest lodges, and lawyers’ offices. It was therefore easy for us to calculate Gemrocks footprint ourselves without having to hire external services.

Measuring your carbon footprint with a specialized consultant office can be worth tens of thousands of USD and is generally inaccessible for small companies like the ones that dominate the crystal industry.

Free carbon footprint calculators on the internet on the other hand are by far not sufficiently detailed to provide a real carbon footprint like a company is producing it. They are nice fun tools for personal carbon footprint calculations, but not for professional company footprints

How does the methodology work?

The tables used by Doemench to calculate the carbon footprint of the port consist of hundreds of conversion factors that convert the amount of money spent for certain materials, goods, or services into an amount of CO2 gas being emitted by this product. Therefore it is possible to point out that practically the entire calculation data of the footprint can be obtained from the organization’s accounting. It is not required that the specialist who calculates the footprint is physically present in the company. It all can be done virtually from a distance.

Because of this, we can offer you to calculate your carbon footprint without the need for us to travel and visit you. If you are interested in knowing your carbon footprint we simply will send you a written instruction on how to organize and group together the accounting information.

To give an example:

- How much money (in total) was spend on gasoline for your companies car per year (and which gasoline: diesel, biodiesel, gasohol, GNP,…)?

- How much money was spent in total in shipping per year?

- How much money was spent in packaging material per year?

By not paying an outside consultant to do this work and investing your own time to organize the data, you can significantly reduce the cost of doing a carbon footprint calculation.

Once you have compiled all the data required, you simply send us the filled out report. We will get back to you for a consultation feedback in case we see that the format was not filled out correctly or is incomplete. And once the data is complete we fill this data into the calculation sheets and get your carbon footprint calculation. You will then receive a report from us detailing your carbon footprint.

Basic carbon footprint calculation

Recommended for start-ups with less than 100.000,- USD annual income- 60 minutes meeting to explain the process and define steps and timeline+ Manual

- Manual explaining the method of data collection

- Email support for questions during the data collection process.

- Live WhatsApp chat support during data collection

- Feedback video call to clarify questions after receiving your data

- Carbon footprint calculation based on data delivered by you

- Final report explaining your carbon footprint

- Proposals to reduce your carbon footprint

- Final meeting to clarify questions about the report

- Free promotion of your company’s environmental effort on our website and our social networks

Professional carbon footprint calculation

Recommended for business owners that require a deeper insight- 60 minutes meeting to explain the process and define steps and timeline

- Manual explaining the method of data collection

- Email support for questions during the data collection process.

- Live WhatsApp chat support during data collection

- Feedback video call to clarify questions after receiving your data

- Carbon footprint calculation based on data delivered by you

- Final report explaining your carbon footprint

- Proposals to reduce your carbon footprint

- Final meeting to clarify questions about the report

- Mention of your company’s environmental effort on our website.

Complete footprint calculation

The luxury version of our carbon footprint calculation- 60 minutes meeting to explain the process and define steps and timeline

- Manual explaining the method of data collection

- Email support for questions during the data collection process.

- Live WhatsApp chat support during data collection

- Feedback video call to clarify questions after receiving your data

- Carbon footprint calculation based on data delivered by you

- Final report explaining your carbon footprint

- Proposals to reduce your carbon footprint

- Final meeting to clarify questions about the report

- Free promotion of your company’s environmental effort on our website and our social networks

Be an industry leader

Why choose Gemrock?

All our workers are hired under formal working contracts and provided with all legally required health, labour and retirement benefits.

We are going to great length to find the right process for each type of stone in order to achieve the best possible polish.

During our lapidary production we have a rigurous review process in place that filters out any product that shows the tyniest scratches.

We strive for perfect shapes in all our products, even if this means an extreemly high effort in carving.

Even if handmade piece by piece, we do offer standartized sizes that do not vary more than 2 to 3 mm. This improves the pricing process of our clients.

All our workers are hired under formal working contracts and provided with all legally required health, labour and retirement benefits.

We are going to great length to find the right process for each type of stone in order to achieve the best possible polish.

During our lapidary production we have a rigurous review process in place that filters out any product that shows the tyniest scratches.

We strive for perfect shapes in all our products, even if this means an extreemly high effort in carving.

Even if handmade piece by piece, we do offer standartized sizes that do not vary more than 2 to 3 mm. This improves the pricing process of our clients.

We are constantly improving our production process in order to achieve shorter production times while maintaining quality. Also we are trying to save water and energy.

Free Gemrock Learning Resources

Free Gemrock Learning Resources

Connect wherever you want and can

Connect wherever you want and can

Get in Touch

+51 994104206

gemrockinternational@gmail.com